The Role of Grinding Media Ball in Comminution

Our grinding media are available in a wide range of types and sizes to suit various milling and comminution processes. Among these, beads are a popular type of grinding media, valued for their uniform shape, composition, and cost-effectiveness, making them essential for efficient material processing in many industrial applications. The available sizes are specified in mm (millimeters), ensuring precise selection for your equipment.

We adhere to standard specifications for our grinding media, providing consistent quality and reliability that meet industry norms. Our products are highly durable, designed to withstand rigorous milling processes and deliver long-lasting performance. For optimal results, certain types of grinding media are recommended for specific applications, such as bead mills or food processing environments.

Industries served include mining, ceramics, paints, coatings, and agrochemicals, where specialized grinding media like zirconium silicate beads offer durability and cost-effectiveness. In the manufacturing of alumina media, specific impurities such as MgO are intentionally added to influence properties like grain growth during sintering.

All product information and specifications provided are up-to-date to ensure you have the most current data for your application. Note: For best performance, select the recommended size and type of media for your specific milling process.

For further guidance, quotes, or technical support regarding grinding media selection, please contact our team.

Introduction to Comminution

Comminution is a fundamental process in many industries, involving the reduction of raw materials into fine powders or smaller particles. This step is essential in sectors such as mining, cosmetics, and paints, where achieving the right particle sizes can directly impact product quality and performance. Grinding media, including grinding balls and ceramic grinding media, are at the heart of comminution, as they facilitate the breakdown of materials through repeated impact and friction. The selection of appropriate grinding media is crucial to optimize grinding processes, ensuring efficient size reduction and consistent results. At MSE Supplies, we understand that each application has specific needs, which is why we offer a comprehensive range of grinding media—including forged steel, zirconium oxide balls, and alumina—to help customers achieve their desired outcomes. Whether you are processing minerals, manufacturing paints, or developing cosmetic products, our grinding media solutions are designed to meet the unique requirements of your industry and optimize your grinding processes.

What is the Grinding Media in a Ball Mill?

In a ball mill, the grinding medium is typically spherical or cylindrical balls made of steel, ceramic, or other materials. The material to be ground is loaded into the ball mill along with the grinding medium, and as the mill rotates, the grinding medium crushes and grinds the material, effectively reducing its particle size.

Types of Grinding Media

Selecting the right type of grinding media is essential for achieving optimal results in any grinding application. There are several types of grinding media available, each offering unique characteristics tailored to specific materials and processes. Forged steel grinding media, for instance, is renowned for its high hardness and exceptional impact resistance, making it ideal for grinding hard materials and delivering long-lasting performance. Ceramic grinding media is preferred when less contamination is required, especially in applications involving soft materials or where product purity is critical. Zirconium oxide balls stand out for their high hardness and durability, providing reliable performance in demanding environments. The choice of grinding media depends on factors such as the material being processed, the desired level of contamination, and the specific requirements of the grinding process. By offering a wide selection of grinding media—including forged steel, ceramic, and zirconium oxide balls—MSE Supplies ensures that customers can select the best option for their unique applications.

Grinding Media Characteristics

The performance of grinding media is determined by several key characteristics, including ball size, density, and hardness. Ball size plays a significant role in grinding efficiency; smaller balls are particularly effective for producing fine powders, while larger balls are better suited for coarse grinding. Density is another important factor, as denser grinding media can deliver more energy to the material, enhancing the grinding process. Hardness is critical for wear resistance, ensuring that the grinding media maintains its shape and effectiveness over time, even when processing abrasive materials. At MSE Supplies, we offer a diverse range of grinding media with varying sizes, densities, and hardness levels to meet the specific needs of different applications. By carefully selecting the right combination of these characteristics, customers can optimize their grinding processes, reduce wear, and achieve the desired particle sizes efficiently.

Ball Mill Operation

A ball mill is a versatile piece of equipment used to grind materials into fine powders using grinding media such as grinding balls. During operation, the ball mill rotates, causing the grinding media to tumble and collide with the material, effectively breaking it down into smaller particles. The choice of grinding media—including its size, quantity, density, and hardness—is critical to the efficiency of the ball mill and the quality of the final product. Selecting the appropriate ball size and quantity ensures optimal grinding action and helps achieve the desired particle sizes. Additionally, considerations such as potential contamination and the specific properties of the material being ground play a role in media selection. At MSE Supplies, we provide a wide range of grinding media and ball mills designed to meet the specific needs of various industries, ensuring that customers can achieve consistent, high-quality results in their grinding operations.

What are Grinding Media Balls Used for?

Grinding media balls are used in ball mills and other industrial machinery for pulverizing materials into fine powders. They are commonly used in the mining, cement, ceramics, and chemical industries for grinding materials such as ores, coal, pigments, and chemicals. The grinding media balls help to reduce the particle size of the material being processed by exerting mechanical force through impact and friction, resulting in the desired fineness for further processing or use. Different types of grinding media balls are available, including steel balls, ceramic balls, and other specialized materials, each suited to specific applications and operating conditions.

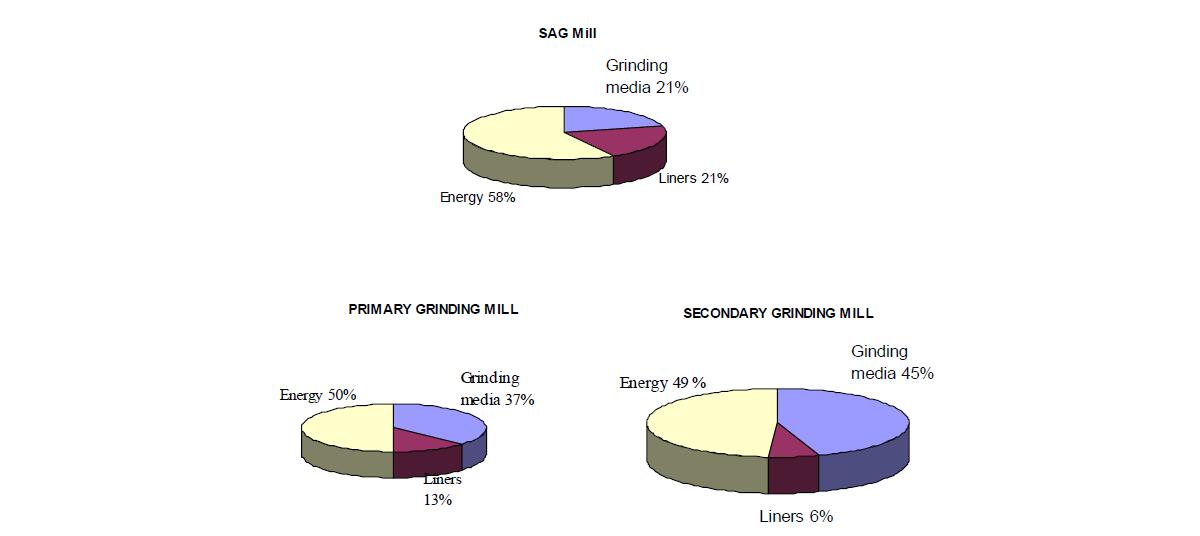

Grinding Media Ball have a significant impact on the performance of grinding mills in terms of product size distribution, energy consumption and grinding costs. The below Figure shows main grinding costs for the specified mills. Considering the contribution of grinding media ball costs toward overall grinding costs, examining the possibility of minimizing them is worthwhile.

With over 20 years with experience in supplying for Mining, Cement, Thermal Power & chemical industries and with continued development of advanced grinding media ball technology have established Allstar at the forefront of grinding media ball manufacturers.

Allstar expertise fully assure to provide the most efficient solution for your particular grinding requirements.

In the long term, the effectiveness of grinding media ball must be measured by the final cost per ton of product efficiently ground. Allstar advanced manufacturing manufacturing methods and materials guarantee the maintenance of the diameter tolerances and correct structures vital to consistent performance and long life of grinding media ball. The Allstar Grinding Media Ball have a uniform hardness from surface to core, thus maintaining very good wear properties down to very small diameters. The grinding media ball has not only a hard outer layer for long life, but also coupled with a tough, resilient core giving good impact resistance. All of the supplied grinding media ball are rigorously tested to ensure the specifications to be in accordance with the requirements. Visit at the https://www.grindingball.com

What is the HS code for Grinding Media Ball?

The Harmonized System (HS) code for grinding media balls can vary depending on the specific type and material of the grinding balls. Generally, for grinding media balls made of steel, the HS code falls under:HS Code 7326.11- This code is for grinding balls and similar articles for mills, forged or stamped, but not further worked.

Polishing for Grinding Ball before Chemical Analysis and Hardnes