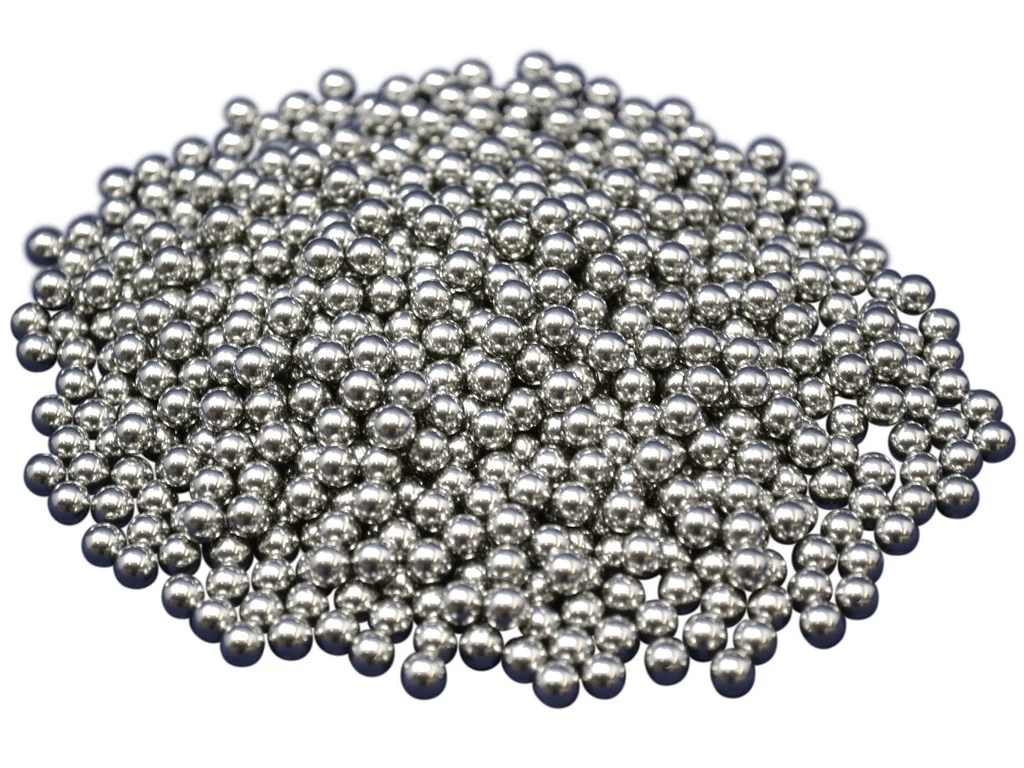

Grinding Media Ball | Component In Industrial Milling

Grinding Media Ball are spherical objects used in grinding and milling processes to crush or grind materials into fine powders. They are commonly used in industries such as mining, cement, chemical processing, and mineral processing. The primary purpose of grinding media balls is to facilitate the reduction of particle size in mills, ensuring uniformity and efficiency in the production process.

Materials Used in Grinding Media Balls

Grinding media balls are manufactured from various materials depending on the application and desired properties. Common materials include steel, stainless steel, cast iron, ceramic, and high-chrome alloys. Steel balls are widely used for their durability and cost-effectiveness. Ceramic balls are preferred for their high hardness, chemical resistance, and suitability for abrasive materials. The selection of material impacts wear resistance, efficiency, and the overall performance of the milling process.

Grinding Media Ball Manufacturing Process

The production of grinding media balls involves processes such as casting, forging, and sintering. Casting involves pouring molten metal into molds to achieve the desired size and shape. Forging uses high-pressure techniques to form dense, uniform balls with enhanced mechanical properties. Sintering is typically used for ceramic grinding media, where powdered material is compacted and heated to form solid balls. Each manufacturing method ensures precise control over hardness, size, and uniformity.

Applications Across Industries of Grinding Media Balls

Grinding media balls are used in a variety of industrial applications. In mining, they are essential for grinding ores to extract metals such as gold, silver, and copper. Cement and construction industries use them to grind raw materials and clinker to achieve the desired particle size. Chemical processing industries utilize grinding media balls to produce powders for various chemical compounds. Their versatility allows them to be applied wherever size reduction and material consistency are critical.

Grinding Media Ball Size and Shape Considerations

Grinding media balls come in different sizes, typically ranging from a few millimeters to several centimeters in diameter. The size is selected based on the mill type, material characteristics, and desired final product. Uniformity in shape and size ensures efficient grinding and reduces wear on milling equipment. Proper sizing and distribution of grinding media balls help achieve optimal grinding performance and maintain consistency in output.

Technological Advancements of Grinding Media Balls

Modern grinding media balls incorporate technological improvements to enhance durability, efficiency, and wear resistance. Advanced heat treatment, alloying, and coating techniques help improve the hardness and lifespan of the balls. Computer-aided design and quality control systems ensure precise manufacturing and uniform performance. These advancements contribute to increased productivity, reduced maintenance, and lower operational costs in milling processes.

Grinding Media Ball Quality Control and Performance

Quality control is a critical aspect of grinding media ball manufacturing. Inspection processes include checking hardness, density, size distribution, and surface finish. Consistency in material properties ensures reliable performance during grinding operations. High-quality grinding media balls reduce the risk of contamination, minimize breakage, and provide uniform particle size reduction in milling applications.

Conclusion

Grinding media balls are indispensable in industrial milling and grinding operations. Through careful selection of materials, precise manufacturing processes, and technological enhancements, they provide reliable performance in size reduction and material processing. Their role in improving efficiency, consistency, and productivity makes grinding media balls a vital component in multiple industries worldwide.