Cast Steel Ball

Features

Application Areas

• Mineral processing plants

• Power stations

• Cement plants

Main benefits

• No deformation

• Uniform hardness throughout

• High resistance to breakage

Specifications

- CR10-14%

- CR15-18%

- CR19-22%

- CR23-32%

|

Diameter (MM) |

Surface Hardness(HRC) |

Core Hardness(HRC) |

Chemical Composition(%) |

|

15 |

60-66 |

59-65 |

CR 10.00-14.00 C 2.20-3.20 SI 1.00 max. Mn 0.50-1.50 S 0.06 max. P 0.06 max.

|

|

17 |

60-66 |

59-65 |

|

|

20 |

60-66 |

59-65 |

|

|

25 |

60-66 |

59-65 |

|

|

30 |

60-66 |

58-64 |

|

|

40 |

60-66 |

58-64 |

|

|

50 |

60-66 |

58-64 |

|

|

60 |

60-66 |

58-64 |

|

|

70 |

60-66 |

58-64 |

|

|

80 |

60-66 |

58-64 |

|

|

90 |

58-65 |

56-63 |

|

|

100 |

58-65 |

56-63 |

|

|

110 |

57-64 |

55-62 |

|

|

120 |

57-64 |

55-62 |

|

Diameter (MM) |

Surface Hardness(HRC) |

Core Hardness(HRC) |

Chemical Composition(%) |

|

15 |

60-66 |

59-65 |

CR 15.00-18.00 C 2.20-3.00 SI 1.00 max. Mn 0.50-1.50 S 0.06 max. P 0.06 max.

|

|

17 |

60-66 |

59-65 |

|

|

20 |

60-66 |

59-65 |

|

|

25 |

60-66 |

59-65 |

|

|

30 |

60-66 |

58-64 |

|

|

40 |

60-66 |

58-64 |

|

|

50 |

60-66 |

58-64 |

|

|

60 |

60-66 |

58-64 |

|

|

70 |

60-66 |

58-64 |

|

|

80 |

60-66 |

58-64 |

|

|

90 |

58-65 |

56-63 |

|

|

100 |

58-65 |

56-63 |

|

|

110 |

57-64 |

55-62 |

|

|

120 |

57-64 |

55-62 |

|

Diameter (MM) |

Surface Hardness(HRC) |

Core Hardness(HRC) |

Chemical Composition(%) |

|

15 |

60-66 |

59-65 |

CR 19.00-22.00 C 2.00-3.00 SI 1.00 max. Mn 0.50-1.50 S 0.06 max. P 0.06 max.

|

|

17 |

60-66 |

59-65 |

|

|

20 |

60-66 |

59-65 |

|

|

25 |

60-66 |

59-65 |

|

|

30 |

60-66 |

58-64 |

|

|

40 |

60-66 |

58-64 |

|

|

50 |

60-66 |

58-64 |

|

|

60 |

60-66 |

58-64 |

|

|

70 |

60-66 |

58-64 |

|

|

80 |

60-66 |

58-64 |

|

|

90 |

58-65 |

56-63 |

|

|

100 |

58-65 |

56-63 |

|

|

110 |

57-64 |

55-62 |

|

|

120 |

57-64 |

55-62 |

|

Diameter (MM) |

Surface Hardness(HRC) |

Core Hardness(HRC) |

Chemical Composition(%) |

|

15 |

60-66 |

59-65 |

CR 23.00-32.00 C 2.00-3.00 SI 1.00 max. Mn 0.50-1.50 S 0.06 max. P 0.06 max.

|

|

17 |

60-66 |

59-65 |

|

|

20 |

60-66 |

59-65 |

|

|

25 |

60-66 |

59-65 |

|

|

30 |

60-66 |

58-64 |

|

|

40 |

60-66 |

58-64 |

|

|

50 |

60-66 |

58-64 |

|

|

60 |

60-66 |

58-64 |

|

|

70 |

60-66 |

58-64 |

|

|

80 |

60-66 |

58-64 |

|

|

90 |

58-65 |

56-63 |

|

|

100 |

58-65 |

56-63 |

|

|

110 |

57-64 |

55-62 |

|

|

120 |

57-64 |

55-62 |

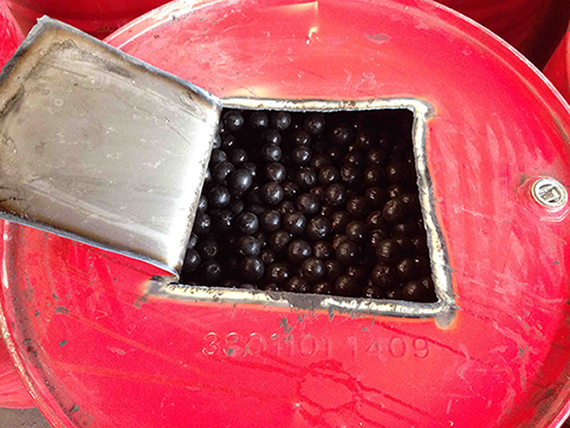

Package

Type A. Steel Drums

N.W. 850KG-900KG/Drum ; G.W. 867KG-917KG/Drum

Type B. Bulk Bags

N.W. 1000KG/Bag ; G.W. 1002KG/Bag

We are the most leading and certified manufacturer of high quality and reliable grinding media. Our company has an experienced team who has better expertise in manufacturing and supplying optimized products and solutions. Our product solutions are ideal for cement plants, quarries, power stations and mineral processing, chemical industries and much more.

The grinding media of Allstar also includes grinding steel ball, grinding media ball and grinding ball. It is significant to note that our product solutions are featured by high resistance, low breakage, and uniform hardness. Apart from that, we also provide cast steel ball which is support by scientific manufacturing techniques and advanced manufacturing equipment. It means that our company is well-equipped to bring our clients high quality and most consistent products like cast steel ball at very reasonable rates.

A Guide for Buying the Cast Steel Ball

In order to improve the better working capacity, you can need to access the best steel ball. It can reliably increase the production capacity and other. You can get the brief detail about the cast steel ball. We manufacture such kind of the ball at the cheap price. We help you to learn more about steel ball is used for various purposes. Moreover, it is used in the cement building material, thermal power, chemical engineering and others. It is best for the industrial preparation purpose. We are the best exporter in the present time for selling the quality steel bar.

The steel ball includes copper, brass, stainless steel, cast iron and lot more materials. It is highly demanded one for the fitting purpose. You can see our featured product like,

1) Hot rolled steel ball

2) Grinding rod

3) Grinding cylpebs and others

We manufacture the casting steel ball with the high-quality carbon and alloy steel. We make this one with the high density and strength that suitable for the grinding needs. This is available in different size. You cannot worry about to get the ball with us. We sell a wide variety of ball in the market with the different shapes based on the user needs.

Get the featured ball:

We deliver it at your doorstep in different forms. Before buying it, you can check the chemical composition, core hardness, surface hardness and others. You can consider lot more things while buying the cast steel ball with us. We are able to produce tons of balls every year. We are the world’s leading manufacturer to make the one with the perfect finish. It is suitable for the cement plants, power stations, and chemical industry. Our company is highly reputable one in the industry and delivers the quality ball within a very short amount of time to the customer.

It is the best investment for the people and assures the customer satisfaction. Over the years, we are highly experienced one in the manufacturing process. We invite you to invest money in the steel ball. This one improves the operational efficiency and profitability. It can reliable reduce the cost and loss of the material damage in your industry. You can avail of huge benefits with the different materials. You cannot afford to spend a huge amount of money for it. You just spend less amount of money for this call and obtain the perfect benefit.

Key Features:

It is an effective feature of metal mold that makes the structure much uniform as well a finer. Apart from that, our latest heat treatment method and metal mold make our products durable.

It is significant to know that these steel balls come with better crash fatigue conflict the minimal abrasive wear. For gathering additional details regarding the cast steel ball, you can hire our official website where you can collect all significant details regarding our product solutions. It is vital to check the quality, durability, reliability, size and other important aspects before selecting any one. We have an extensive range of steel balls that will perfectly suit all application areas and needs.

Significant Benefits:

We manufacturer the steel ball for several applications areas, including:

1. Mineral processing plants

2. Cement plants

3. Vertimills / Ball Mills

4. Power stations

We offer steel balls in different diameters, surface hardness, and core hardness. Additionally, the chemical composition will vary from one steel ball to another one, so you can consider it properly before making any decision. Our specification table helps you to choose the right kind of steel ball without any confusion. We use durable materials to make our steel balls robust and durable. The best manufacturing technology included in our steel balls bring you numerous benefits, including:

1. No deformation

2. Even hardness throughout

3. Increased wear resistance

4. Enhanced resistance to the breakage