How are grinding balls made?

Views: 1425 Update Date:Sep 04 , 2023

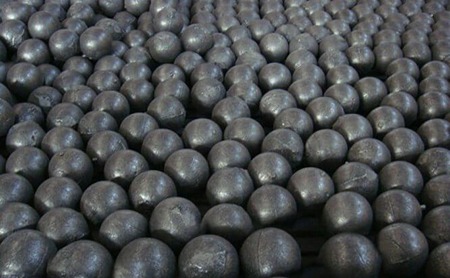

Grinding balls, often taken for granted, are integral components in various industries, especially mining and manufacturing. These unassuming spheres play a pivotal role in the process of pulverizing materials into fine powders. But how exactly are grinding balls made?

Prev: What are Grinding Balls Used for?

Next: What is the hardness of grinding media ball?

1. Raw Material Selection

A grinding ball commences with the meticulous selection of raw materials. Typically, manufacturers opt for high-quality alloy steel, a blend of iron, chromium, manganese, and carbon. This alloy imparts durability and resistance to wear, making it ideal for the demanding environments grinding balls will encounter.2. Melting and Formation

The chosen raw materials are subjected to extreme temperatures, often exceeding 2,000 degrees Celsius, in a furnace. The molten steel is then meticulously poured into spherical molds, which resemble oversized golf ball dimples. This initial step lays the foundation for the grinding ball's eventual shape and structure.3. Heat Treatment

Following formation, grinding balls undergo a critical heat treatment process. By subjecting them to precise temperature control and rapid cooling, known as "quenching," manufacturers optimize the balls' hardness and toughness. This ensures that grinding balls can withstand the harsh conditions of the grinding process.