Why select high chromium alloy cast ball for cement industry?

What kind of high chromium alloy cast balls used in the construction industry will be more cost-effective? In terms of chemical composition, there are dozens of different materials from low chromium to high chromium, which can be described as a wide variety. In order to standardize the industry standard, let people have a clear understanding of the chromium alloy cast ball from a rational point of view, the national standard for cast grinding balls GB/T17445-2009 stipulates that the chromium content of low chromium balls is 1%-3%, and the hardness HRC≥45; alloy ball chromium content 4%-6%, hardness HRC≥47; medium chromium alloy ball chromium content 7%-10%, hardness HRC≥48; high chromium alloy ball chromium content ≥10%-14%, hardness HRC≥58; the chromium content of the special high chromium ball exceeds 14%, and the hardness HRC≥58.

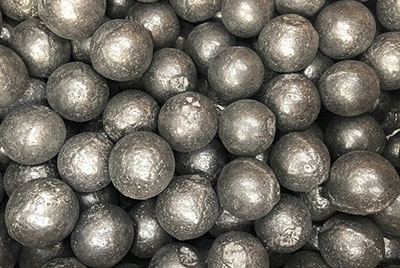

At present, most of the grinding media used in cement industry are high-chromium balls. With the continuous development of cement grinding technology, the specific surface area and fineness of cement are required to be even higher. As a cement company, the correct selection of grinding media is particularly important. The abrasive body with high wear resistance can not only improve the grinding efficiency, reduce the time of stopping the ball filling and the number of times of starting and stopping, but also extend the clearance cycle, reduce the labor intensity of the workers, and improve the grinding machine at the same time, ensuring the quality of abrasives, and reducing power consumption and abrasive consumption are of great significance.